CURRICULUM VITAE

Henry B. Bonar, II, P.E.

Qualifications

The University of Florida – B.S. Mechanical Engineering

Licensed Professional Engineer

CEO – Bonar Engineering and Construction Company, Inc.

President – Bonar Engineering, Inc.

Past Board of Directors and Committee Experience, Memberships

ASME (American Society of Mechanical Engineers), member since 1970.

ASHRAE (American Society of Mfg. Refrigeration & AC Engineers), member since 1969.

IIAR (International Institute of Ammonia Refrigeration), Past-President 1986 – 1987; Charter Member 1971 and life member.

IARW (International Association of Refrigerated Warehouses), member

LEPC (The Local Emergency Planning Committee, Jacksonville, Florida), committee member.

TRRF (The Refrigeration Research Foundation), Co-Chairman, refrigeration engineering committee.

Ortega United Methodist Church, Jacksonville Florida, Past Board of Directors

Speaking Engagements and Teaching

TRREF/WFLO - Oklahoma City, OK, and Atlanta, GA, Instructor, Refrigeration Training Schools

IIAR - Industrial Refrigeration Workshops, 1992, Chicago, IL, 1993, Manhattan, KS, and 1994, Charlotte, NC, Refrigeration Instructor

IIAR - Industrial Ammonia Refrigeration Safety Seminar, 1988, Jacksonville, FL, and Citrus Hill, Lakeland, Florida

PSM (Process Safety Management), Trainer Refrigeration Personnel

National Fire Academy's Chemistry of Hazardous Materials 80 Hour Course

Job-Related Honors, Awards

IIAR 1985 Member of the year

LEPC 2001 Florida State Emergency Response Commission for Hazardous Materials Thomas Yatabe Certificate of Outstanding Achievement

LEPC 2006 Florida State Emergency Response Commission for Hazardous Materials Thomas Yatabe Certificate of Outstanding Achievement

IIAR 2008 Honorary Life Member

Patents/Grants/Research

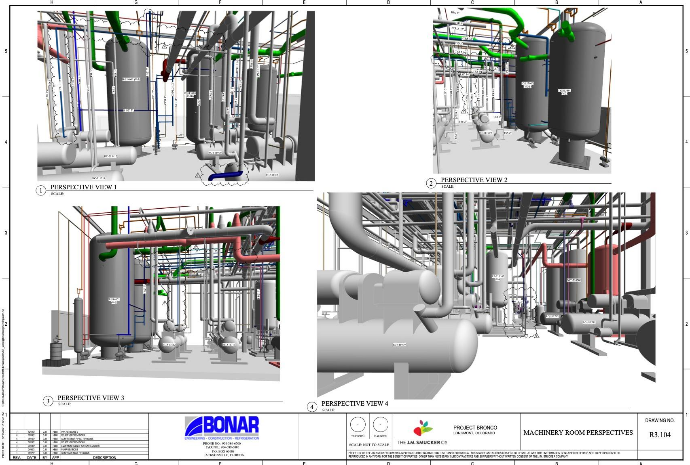

1981 - Patent No. 4,282,717 - Oil Separator and Heat Exchanger For Vapor Compression Refrigeration System

1983 – Installation of first screw compressor Thermosyphon oil cooling system.

2002 – Patent No. 6,484,498 B1 - Apparatus and method for converting Thermal to electrical energy.

2012 – University of North Florida grant for evaluating expander apparatus for thermo to electrical energy.

2014 – UNF grant for fluid amplifier, mechanical-free refrigeration system using solar thermo heat sinks.

Publications

Florida Comes of Age, The History of Florida’s Refrigeration and Frozen Food Distribution. Library Of Congress Catalog Card Number 97-094456, 1997 by Henry B. Bonar, II.

Industry in the Cold, Published by International Institute of Ammonia Refrigeration. 1986 Edited by Henry B. Bonar, II.

"Convenience Store Explores The Potential of Ammonia," Published by Gordon Duffy, Publishing Director, Engineered Systems, Vol. 7, No. 1, January/February 1990. Article/Edited.

"DON'T TAKE Programmable Controllers On Ammonia Systems For Granted," Written by Henry B. Bonar, II, Published by Engineered Systems, Vol. 8, No. 2, March 1991. Article.

Cleanup Procedures For Refrigerant Ammonia Spills, Excerpts by William A. Ostner, Published and Edited by Henry B. Bonar, II, 1984.

"Refrigeration Design Safety," Lecture by Henry B. Bonar, II, for RETA - Anaheim, CA, 1985.

"Industrial Refrigeration Design Safety," Paper by Henry B. Bonar, II, Transactions of the 1988 Citrus Engineering Conference, Vol. XXXIV, March 1988.

“A History of Thermosyphon Oil Cooling” Paper by Henry B. Bonar, II given at 1989 IIAR March 12-15 Annual Meeting

"Effects of Increased Energy Cost On Refrigeration Warehouse Construction," Written by Henry B. Bonar, II, ASHRAE Journal, Vol. 16, No. 11, 1974, Article.

"Technical Aspects of Recirculated Ammonia," Lecture by Henry B. Bonar, II, for IIAR - Atlanta, GA, 1996.

“Water Dump Tanks: Fact or Fiction?” Paper at 1998 IIAR March 15-18 Annual Meeting.

“Proper Application of Good Practice with Ammonia Pumps” Paper at March 19-22, IIAR 2000 Annual Meeting

“Single vs Two-Stage Efficiency Considerations” Paper at IIAR 2002 March 17-20, 2002 Annual Meeting.

"Refrigeration Systems - No Sweat, Desiccants and Industrial Refrigeration," Written by Henry B. Bonar, II, Process Cooling & Equipment, May 2004, Article.

PE Registrations

Alabama, Arizona, Arkansas, California, Colorado, Delaware, Florida, Georgia, Idaho, Illinois, Indiana, Kansas, Kentucky, Louisiana, Maine, Maryland, Massachusetts, Michigan, Mississippi, Missouri, Nebraska, New Hampshire, Nevada, New York, North Carolina, Oklahoma, Ohio, Pennsylvania, South Carolina, Tennessee, Texas, Virginia, West Virginia, Washington, and Wisconsin

Profile Summary

Mr. Bonar was born February, 1941, and graduated from Chamberlain High School, Tampa, Florida, in 1959, and The University of Florida in 1964 with a BSME Degree. Mr. Bonar grew up in refrigeration, his father was active for many years in his own firm in Tampa.

After college, Mr. Bonar's first employment was with Merchants Refrigerating Company, New York, New York, from 1964 to 1967 as an engineer. He was responsible for engineering and construction of new projects for refrigerated warehouses and refrigeration systems.

Employed by Florida Ice Machines and American Refrigeration in Jacksonville from 1967 to 1975 as Director, Treasurer, and Vice President of Engineering, his responsibilities included engineering and project management for industrial refrigeration systems. This included engineering specifications and equipment components, pipe, valves and fittings, as well as insulated structures for low temperature refrigeration and insulated systems.

In 1975, Mr. Bonar formed Henry B. Bonar, II, Proprietorship, and later Bonar Engineering, and Construction Company for the engineering of refrigerated systems and facilities.

As principal, Mr. Bonar's responsibilities include management of a variety of refrigeration projects, overseeing, engineering design specification development for equipment components, insulated structures, support and control systems.

Mr. Bonar is a mechanical engineer specializing in refrigeration systems and controls. He has 30 years of experience in the field including ammonia, glycol, CO2, refrigeration systems.

Legal/Expert Witness

1977 Health Foods, St. Augustine, FL – Insulation condensation

1979 Queen Foods, Birmingham, AL – Freezing capacity

1982 Seabrook Farms, Seabrook, NJ – Tornado damage

1995 Cargill Foods, Jacksonville, FL – OSHA fines

1998 New Orleans Cold Storage, New Orleans, LA – Ammonia valve release

2008 Service Cold Storage, Ft. Lauderdale, FL – Ammonia leak

2008 Valley Foods, Harlingen, TX – Ammonia leak, air unit fan damage

2008 Springfield Foods, Springfield, MA – Damaged ammonia air unit

2009 American Cold Storage, Louisville, KY – Ammonia safety employee death

2009 New Orleans Cold Storage, Charleston, SC – Ammonia release, pipe corrosion

2009 Premium Pork, Hospers, IA – Ammonia-related fire

2009 Imperial Freezer, Sanford, NC – Temperature abuse, refrigeration

2009 Global Foods, Mentone, IN – Fire

2009 Polar Cold Storage, Dillon, SC – Temperature abuse, blast freezing

2009 Terminal Freezers, Watsonville, CA – Ammonia coil leak

2009 Houston Central Industries, Houston, TX – Ammonia air unit damage

2010 Wells Dairy, Sioux City, IA – Ammonia valve failure

2010 C&S Wholesale Grocers, North Hatfield, MA – Appeal of EPA Citation

2010 Millard Refrigerated Services, Theodore, AL – Ammonia pipe failure

2011 Midway Cold Storage, St. Paul, MN – Air unit hot gas pan failure

2013 Port Newark, Newark, NJ – Temperature abuse, product storage

2014 Mountaire Farms, Lumber Bridge, NC – Operational ammonia release, employee injury

2014 Fanny May Flowers, Cleveland, OH – Fire, ammonia refrigeration system

2016 Dick Cold Storage, Columbus, OH – Fire, ammonia refrigeration system

2019 Sanderson Farms Expert witness in appeal of OSHA violations.

2021 Keller and Heckman California Dairy products

Sample Project Experience

Hillshire/Kahn's (Sara Lee), Claryville, Kentucky - Design 40,000 SF refrigerated facility, including structural, refrigeration, and electrical systems.

Sunbelt Cold Storage, Gadsden, Alabama - Design and construction of 40,000 SF of storage and blast freezing.

Spartan Foods, Inc., Grand Rapids, Michigan - Included design of new ammonia refrigeration system. A new 40,000 SF refrigerated distribution cooler and docks.

Georgia Freezer Company, Pendergrass, Georgia – Design and construction of a 368,131 SF distribution storage facility including centralized refrigeration system, blast freezers and offices.

Anheuser-Busch Companies, Inc., Jacksonville, Florida - A $400,000.00 design of five (5) ammonia water chillers.

Sanderson Farms, Inc., McComb, Mississippi - Design of a 400,000 SF central ammonia refrigeration system for poultry freezing and cooling. The project included multi-freezing and storage.

Publix Super Markets, Inc., Deerfield Beach, Florida - Design of a 1,230,000 SF central refrigeration system for dairy manufacturing and frozen distribution facility. The project included multi-purpose cooling and freezing of dairy products.

North Carolina State Ports Authority, Wilmington, North Carolina – Design and construction of 33,000 SF Produce Cold Treatment import refrigerated structure.

Modern/Cuddy Storage and Freezing, Marshville, North Carolina - Design of a 60,000 SF multiple freezer and cooler storage distribution facility including blast freezers and super-blast of poultry products.

Sample Project Experience (Cont’d.)

Columbus Cold Storage, Columbus, Ohio - Design of a 247,189 SF refrigerated facility and its central ammonia refrigeration system for frozen food storage and distribution.

Rotelle, West Point, Pennsylvania - Design of a 300,000 SF refrigeration system for major distribution center for order picking of freezer products, via tiered, automatic, product conveying system with special design temperature tempering vestibules.

Dick Cold Storage, Columbus, Ohio - Design 60,000 SF refrigerated facility and ice manufacturing plant, design included structure, insulation refrigeration, and electrical system.

SYSCO, Hampton, Virginia – Construction of 3,000 SF of multiple temperature refrigerated distribution, included structural, insulation refrigeration, and electrical system.

Publix Super Markets, Inc., Jacksonville, Florida - 350,000 SF, $4,200,000 design of central ammonia refrigeration system for frozen food distribution facility including multi-purpose cooling and storage of products.

Mayasal Shrimp, refrigeration addition, Guatemala City, Guatemala.

Midsouth Ice Company, Atlanta, Georgia - Design and construction of a 36,666 SF ice manufacturing facility with production capacity of 1,000 ton/day of ice. Facility includes multi-temperature processing rooms, ice rakes, and automated palletizing production.

WLR (Cassco), Harrisonburg, Virginia - Design of a 65,189 SF freezer/ refrigeration system and 8 blast freezers.

Safe Harbor Seafood, Mayport, Florida – Design and construction of 25,000 SF refrigerated freezer and cooler. Project also included a central ammonia refrigeration system and underfloor heating system. 1993

Hillshire Farms (Sara Lee), New London, Wisconsin - Design of a central ammonia refrigeration system for a 600,000 SF meat processing facility.

Stanford Refrigerated Services, Macon, Georgia – Design and construction 200,000 SF warehouse, including blast freezers, dock and office.

Arkansas Refrigerated Services, Fort Smith, Arkansas – Design and construction of150,000 SF warehouse, including blast freezers and docks.

Sanderson Farms, Inc., Moultrie, Georgia – Design of a 400,000 SF central ammonia refrigeration system for poultry freezing and cooling. The project included multi-freezing and storage.

Lanier Cold Storage, Gainesville, Georgia – Design of 232,000 SF refrigeration warehouse including freezers, blast freezers, dock and offices.

Sanderson Farms, Inc., Waco, Texas – Design of a 400,000 SF central ammonia refrigeration system for poultry freezing and cooling. The project included multi-freezing and storage.

New Orleans Cold Storage, Jourdan Road Facility, Port of New Orleans, Louisiana – Design and Construction of 185,000 SF, $9.4m facility, including freezers, blast freezers, dock and office for port operation. 2007

Gulf Coast Cold Storage, Pascagoula, Mississippi – 165,000 SF warehouse conversion and construction, including freezers, blast freezers and dock for existing and new freezer conversion.

Coors, Elkton, Virginia – Design of brewery central ammonia refrigeration system. Included 40 fermenters and heat exchangers. 2007

Sanderson Farms, Inc., Kinston, North Carolina – Design of a 450,000 SF $9.1m, central ammonia refrigeration system for poultry processing, freezing and cooling. The project included multi-freezing and storage. 2009

Sample Project Experience (Cont’d.)

Puerto Rico Supplies (Hibiscus Properties), San Juan, Puerto Rico – Construction of a $15m, 200,000 SF facility and design and construction of a central ammonia refrigeration system for freezer and cooler storage, as well as candy processing. 2010

US Army Corps of Engineers, Cold Regions Research and Engineering Lab, Keene, New Hampshire – converted refrigerated test facility from Freon to Ammonia system. 2013

Nestle, Bayamón, Puerto Rico – Design and construction of a new $4.7m distribution facility. 2013

Mooresville Ice Cream, Statesville, North Carolina – Design and construction management of Ice Cream Freezer addition. 2013

Gainesville Ice, Gainesville, Florida – Design and construction of 41,000 SF freezer and ice processing room. 2013

Sanderson Farms, Inc., Palestine, Texas – Design of a central ammonia refrigeration system for 400,000 SF poultry freezing and cooling facility. The project included multi-freezing and storage. 2013

Sanderson Farms, Inc., St. Pauls, North Carolina – Design of a $10m refrigeration system for new poultry processing plant. 2015

Sysco/Freshpoint Foods, Trujillo Alto, Puerto Rico – Addition of refrigerated space. 2015

Fresh Farms, Ltd., Trinidad, West Indies – Perishable distribution center design. 2015

Publix Super Markets, Inc., Deerfield Beach, Florida – Design for addition of four 700 HP compressors, and refrigeration and electrical primary service. 2015

Millennium Port, Boston, Massachusetts – Owner’s Engineering and consulting for new 200,000 SF refrigerated facility and seafood processing. 2016.

Savannah Cold Storage, Savannah, Georgia – Design and construction of 100,000 SF refrigerated and repacking facility for frozen and cooler products for Port of Savannah, Georgia. 2016

Doran Seafood, Independence, Louisiana – Design and construction of new freezer. 2016

Winchester Cold Storage, Inc., Winchester, Virginia – Design and construction of new freezer. 2018

Sanderson Farms, Inc., Tyler, Texas – Design of a $15m refrigeration system for new poultry processing plant. 2018

Costco Wholesale, Fremont, Nebraska - Design of a $20m refrigeration system for new poultry processing plant. 2018

Argos Georgia Ltd., Orlando, Florida – Design and construction of new Chilean bass distribution facility. 2019

Rams Trading Ltd., St. Kitts, West Indies – Design and Supplying of Equipment and Building Materials for Freezer Distribution Facility. 2019

JM Smuckers, Longmont, Colorado -- Redesign and Expand Central Ammonia Refrigeration System with Burns and McDonnell. 2020

Isla Frio, Cidra, Puerto Rico -- Freezer Conversion for Distribution Facility. 2020

Emerging Markets

Russia – Ice Cream Production in Republic of Tatarstan; 1995

Del Tropic, El Salvador – Vegetable Processing /Freezing; 2000

Prestomar, El Salvador – Shrimp Processing /Freezing; 2001

Mayasal, Guatemala City, Guatemala – Shrimp Processing/Freezing; 2001

Moldova/Ukraine – Meat/Fish Processing/Freezing; 2002

India – Processing Vegetable other Perishable Foods; 2005

Egypt – Upper Nile PHP & Proc Facilities for Small Farmers; 2006

Honduras – USDA Cold Chain Processing & DC; 2007

Kosovo – USAID PHP Blueberries and Mushrooms, 11 Sites; 2008

Serbia – USAID/DAI PHP Fruits and Vegetables, Multiple Sites; 2009

Afghanistan – USAID Processing Vegetable and Other Perishable Foods; 2012

Monterey, Mexico – Basal Almacenamiento y Logistica, Freezer and Blast; 2013

Bali, Indonesia – EI/USAID Study for tuna storage solar power refrigeration system; 2014

Odessa/ Kiev, Ukraine – Perishable Food Logistics Study; 2016

Afghanistan – Processing Vegetable and Other Perishable Foods for airport shipments 2017